Reliability

Created and Confirmed

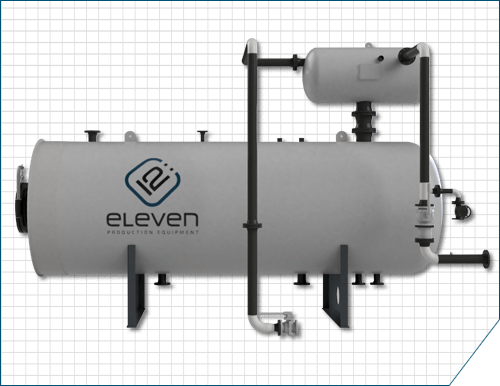

Separators

Known as the workhorse of the upstream processing production equipment, 12:eleven’s separators perform, 24/7. Our designs are based on time-tested technology and extensive field knowledge to bring to our customers a solution that they can depend on. Our engineering staff is constantly studying new, more efficient ways to process your production. From basic separation needs to complex and challenging well streams, our engineers can be leaned on to design your equipment based on the application at hand. By going above and beyond to collect data from our customers, we accurately size equipment and look for ways of cutting costs that are passed on to you.

Our separators come in many different sizes and pressure ratings that allow versatility for the operators looking for equipment based on specific well conditions. We also have several internal designs that are specific to flow patterns of the well and will increase the efficiency and the overall outputs of the separator.

Standard Features

ASME Code or Built to Code but not Stamped

Vertical and Horizontal

2 Phase and 3 Phase Designs

Bare Vessels to Turn Key Package Solutions

50 PSI – 5,000 PSI

2 Phase and 3 Phase Designs

Common Separator Applications

2 Phase Vertical and Horizontal Separators, Low and High Pressure

3 Phase Vertical and Horizontal Separators, Low and High Pressure

Inlet Separators

Slug Catchers

Filter Separators

Scrubbers

More Resources

What Are the Principles of Oil and Gas Separation?

Aug 8, 2022

As simple as the media portrays the oil and gas industry sometimes, in reality, it is quite a sophisticated and...