What You Need to Know About Glycol Dehydration Systems

In the fast-paced and ever-evolving oil and gas industry, glycol dehydration systems are a crucial component in...

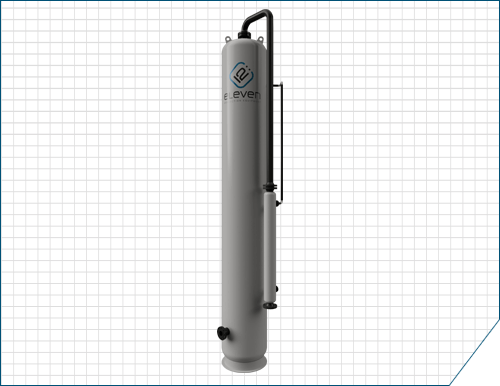

The glycol contact tower is the key component to a dehy system as it is the vehicle used to remove the water from the gas by means of circulating glycol. The tower is a pressure vessel with an integral scrubber and absorber section, each having specific requirements for the tower to function. Contact towers functions to contact lean glycol solution with the wet inlet gas. Various contact mechanisms can be employed with the most commonly used are bubble cap trays.

The scrubber section of the tower removes free liquids from the gas while the absorber section is used to make the contact between the gas and the glycol. The removing of the water vapor from the gas happens in the absorber section of the tower using either bubble cap trays, random packing, or structured packing.

1440 PSIG design pressure rating

Stainless steel mist extractor

ASME code constructed

8 bubble cap trays standard and can add trays for other applications

5:1 turndown ratio

Diameter sizes from 16” to 72”

8 tray capacities equivalent

7:1 turndown ratio

Diameter sizes from 6” to 16”

Designed to handle hotter gas

10:1 turndown ratio

Equivalent to 10 trays

Diameter sizes from 24” to 60”

Jun 26, 2023

In the fast-paced and ever-evolving oil and gas industry, glycol dehydration systems are a crucial component in...

May 31, 2023

In the oil and gas industry, plant operators are constantly trying to find ways to remove contaminants and...

Apr 18, 2023

The oil and gas industry is an essential component of the global economy, and effective extraction and...